9 Essential Business Process Improvement Techniques for 2025

In today's competitive market, operational efficiency is no longer just a goal-it's a fundamental requirement for survival. Hidden inefficiencies in your workflows act as a constant drag on your organization, consuming valuable resources, frustrating employees, and hindering your ability to innovate. Allowing these issues to persist leaves you vulnerable to more agile competitors who have already optimized their operations. The solution lies in systematically identifying and eliminating these pain points, but knowing where to begin can be overwhelming.

This is where proven business process improvement techniques provide a clear path forward. This guide moves beyond abstract theory to deliver a practical roundup of nine powerful methodologies designed to refine, rebuild, and perfect your workflows. We will explore established frameworks like Six Sigma and Lean, revolutionary approaches such as Business Process Reengineering, and continuous improvement philosophies like Kaizen.

For each technique, you will find a clear explanation of its core principles, tangible benefits, and actionable implementation steps. Whether you are aiming for radical, transformative change or small, incremental gains, this article provides the specific tools and insights needed to drive meaningful results. By the end, you'll have a comprehensive playbook for building a more resilient, productive, and competitive organization.

1. Six Sigma

Six Sigma is a disciplined, data-driven business process improvement technique designed to eliminate defects and reduce process variation. Developed by Motorola in 1986, its core objective is to achieve near-perfect quality by limiting defects to just 3.4 per million opportunities. It relies heavily on statistical methods to identify and resolve the root causes of problems rather than just addressing the symptoms.

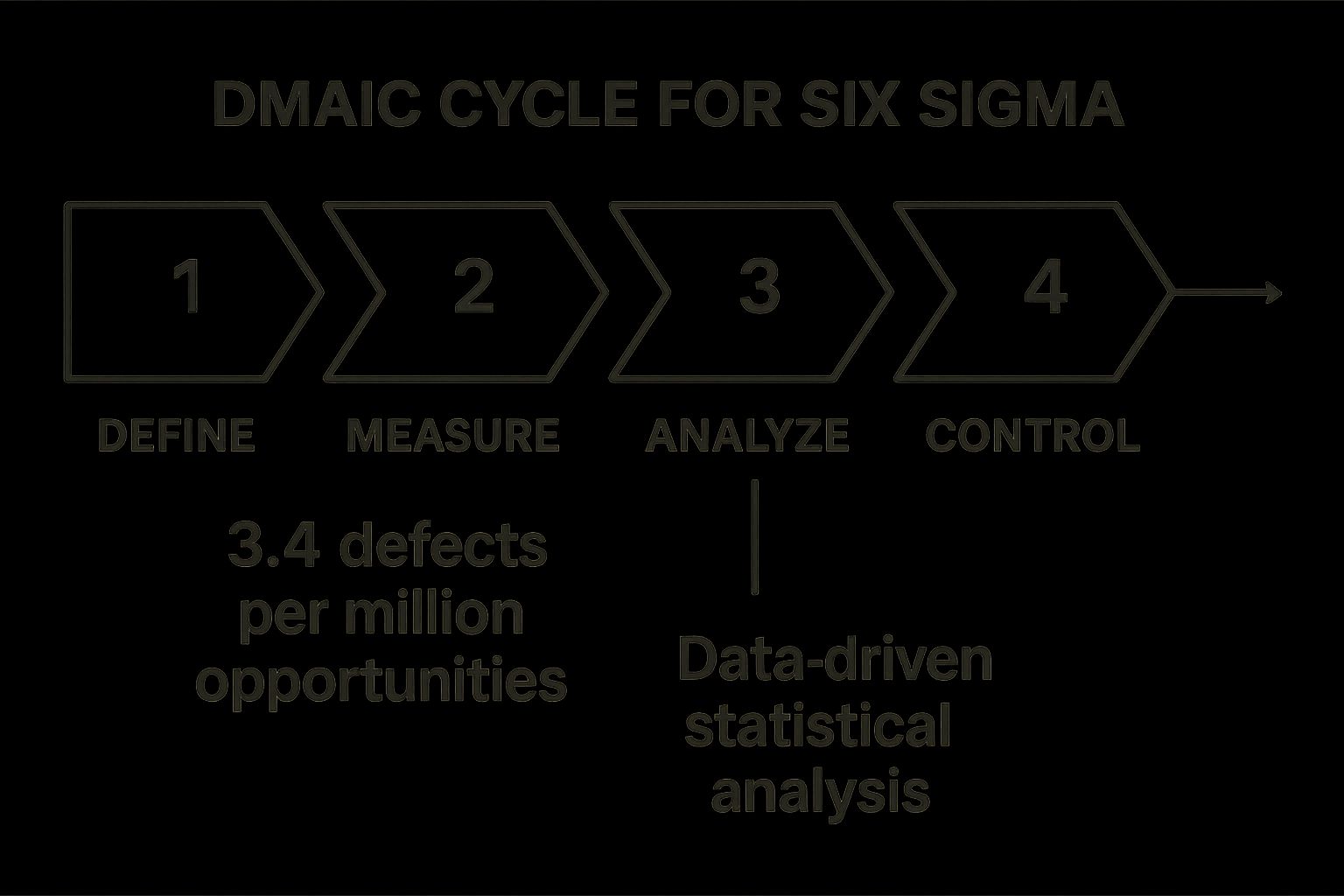

For existing processes, Six Sigma follows a structured five-phase framework known as DMAIC. This methodical approach ensures that solutions are based on verifiable data, leading to sustainable and significant improvements.

How to Implement Six Sigma with the DMAIC Framework

The DMAIC cycle is a roadmap for executing a Six Sigma project. This infographic illustrates the five distinct phases of this powerful process.

The visual flow emphasizes how each phase logically builds on the previous one, using statistical analysis to drive decisions from initial problem definition to long-term control.

Practical Tips for Application

To effectively leverage Six Sigma, consider these actionable steps:

- Start Small: Begin with high-impact, manageable projects that can deliver clear wins and build momentum.

- Secure Leadership Buy-In: Ensure strong, visible support from senior management to allocate resources and overcome organizational resistance.

- Invest in Training: Properly train team members in Six Sigma methodologies, including statistical tools and the DMAIC process, to empower them to lead projects effectively.

- Focus on the Customer: Prioritize processes that are most critical to customer satisfaction to ensure improvements deliver tangible value.

This structured methodology is ideal for organizations looking to make significant, quantifiable improvements in quality and efficiency, as famously demonstrated by General Electric, which reported billions in savings.

2. Lean Manufacturing/Lean Thinking

Lean is a systematic business process improvement technique focused on maximizing customer value while relentlessly eliminating waste. Originating from the Toyota Production System, its core principle is to create more value for customers with fewer resources. Lean identifies and removes non-value-added activities from processes, fostering a culture of continuous improvement, or "kaizen."

Unlike methods that focus solely on defect reduction, Lean thinking targets eight specific types of waste (often remembered by the acronym DOWNTIME): Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra-processing. By addressing these, organizations can streamline operations, improve flow, and become more responsive to customer demands.

Practical Tips for Application

To effectively implement Lean principles in your organization, consider these actionable steps:

- Start with 5S: Use the 5S method (Sort, Set in order, Shine, Standardize, Sustain) to create an organized and efficient workplace. This builds a strong foundation for all other Lean improvements.

- Map Value Streams: Visualize your entire process from start to finish with a value stream map. This helps identify every step, pinpointing exactly where waste occurs and where opportunities for improvement lie.

- Implement Standardized Work: Create clear, repeatable procedures for key tasks. Standardization reduces variation, improves quality, and makes it easier to train employees and identify deviations from the ideal process.

- Create Visual Management Systems: Use tools like Kanban boards and visual dashboards to make process status and performance visible to everyone. This transparency empowers teams to quickly identify and address bottlenecks.

This approach is ideal for businesses aiming to enhance operational speed and efficiency. For a more in-depth exploration of this approach, you can refer to this complete guide to Lean Methodology. Companies like Boeing have famously used Lean to reduce aircraft assembly time by 50%.

3. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a radical business process improvement technique focused on fundamentally rethinking and redesigning core processes to achieve dramatic improvements in critical measures like cost, quality, service, and speed. Unlike methods that seek incremental changes, BPR starts with a clean slate, asking, “If we were starting this company today, how would we do this?”

Popularized by Michael Hammer and James Champy, this approach challenges long-held assumptions and rules that often underlie outdated, inefficient work. BPR aims for quantum leaps in performance by restructuring processes from the ground up, frequently leveraging technology as a key enabler.

How to Implement BPR for Transformational Change

Implementing BPR requires a bold, top-down approach that completely overhauls existing workflows. This diagram highlights the core concept of moving from a fragmented, function-based process to a streamlined, integrated one.

The visual emphasizes the shift from siloed tasks to a holistic, end-to-end process view, which is the foundational principle of successful reengineering projects.

Practical Tips for Application

To successfully implement BPR, consider these strategic actions:

- Secure Executive Sponsorship: BPR is a high-risk, high-reward initiative that demands unwavering support and vision from top leadership to drive change.

- Focus on Customer-Facing Processes: Prioritize redesigning processes that have the most significant impact on customer value and satisfaction.

- Challenge Every Assumption: Question why tasks are performed the way they are and be prepared to eliminate work that doesn't add value.

- Invest in Change Management: Prepare the organization for radical change through clear, consistent communication and robust employee support systems.

BPR is best suited for organizations facing major market shifts or severe performance issues that cannot be solved with minor adjustments. A classic example is Ford, which reengineered its accounts payable process to reduce its staff by 75%, moving from paying upon receipt to paying upon shipment.

4. Kaizen (Continuous Improvement)

Kaizen is a Japanese business philosophy centered on continuous, incremental improvement involving all employees, from the assembly line to the C-suite. The core principle is that small, ongoing positive changes can compound over time to create significant advancements. Rather than waiting for large-scale, disruptive projects, Kaizen promotes a culture where everyone is empowered to identify and implement small enhancements in their daily work.

This approach focuses on eliminating waste (Muda), improving efficiency, and standardizing processes. Its power lies in its simplicity and the collective engagement it fosters, making it one of the most accessible business process improvement techniques.

The visual represents the iterative cycle that drives Kaizen, highlighting how small, tested ideas lead to refined standards and perpetual progress.

How to Implement a Kaizen Culture

Embracing Kaizen means building a new mindset within the organization. While large "Kaizen events" can tackle specific issues, the true value comes from daily habits. For instance, teams can use it to streamline their document workflow automation, making minor adjustments to reduce steps and save time.

Practical Tips for Application

To effectively leverage Kaizen, consider these actionable steps:

- Encourage All Voices: Create systems for employees at every level to submit improvement suggestions without fear of criticism.

- Implement Quickly: Focus on low-cost, low-risk changes that can be implemented immediately. The goal is progress, not perfection.

- Celebrate Small Wins: Publicly recognize and reward individuals and teams for their contributions to build and sustain momentum.

- Provide Basic Training: Equip employees with simple problem-solving tools like the "5 Whys" to help them identify root causes effectively.

This methodology is ideal for organizations seeking to build a resilient culture of proactive problem-solving and operational excellence, as famously demonstrated by Toyota, which implements over a million employee-driven improvements annually.

5. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive management philosophy centered on achieving long-term success through customer satisfaction. Unlike techniques that focus on a single process, TQM ingrains a commitment to quality into every aspect of an organization's culture. Popularized by quality gurus like W. Edwards Deming, it involves all employees in a continuous effort to improve processes, products, and services.

The core principle is that every department and every individual is responsible for quality. This holistic approach ensures that quality is not just a final inspection but a fundamental part of the entire production or service delivery lifecycle, aiming for excellence from start to finish.

How to Implement Total Quality Management

TQM implementation is a cultural shift that requires a systematic, organization-wide commitment. It is built on eight key principles: customer focus, total employee involvement, process-centered thinking, an integrated system, a strategic and systematic approach, continual improvement, fact-based decision making, and effective communication. By embedding these principles, an organization can systematically enhance its operations.

This approach creates a unified effort where every action is geared toward improving quality and achieving customer delight, ultimately leading to better business performance. To dive deeper into operational excellence, you can learn more about improving workflow efficiency.

Practical Tips for Application

To successfully adopt TQM, consider these foundational steps:

- Secure Leadership Commitment: TQM must be driven from the top. Senior leaders must visibly champion, fund, and participate in quality initiatives.

- Focus on the Customer: Continuously gather and analyze customer feedback to define quality standards and guide improvement efforts.

- Empower All Employees: Provide comprehensive training in quality principles and problem-solving tools, and empower employees to make improvements in their own work areas.

- Establish Quality Metrics: Develop clear, measurable goals for quality and review progress regularly to ensure accountability and track improvements.

TQM is ideal for organizations seeking to build a sustainable culture of excellence. Its success is proven by companies like Xerox, which used TQM to regain significant market share by drastically improving product quality and customer satisfaction.

6. Value Stream Mapping (VSM)

Value Stream Mapping (VSM) is a powerful lean management technique used to visualize, analyze, and improve the flow of information and materials required to bring a product or service to a customer. It provides a holistic view of the entire process, from raw materials to final delivery, helping teams identify and eliminate non-value-adding activities, commonly known as waste.

The primary goal of VSM is to create a detailed map of the "current state" of a process. This visual representation highlights bottlenecks, delays, and inefficiencies that are often hidden in day-to-day operations. From there, a team can collaboratively design a more efficient "future state" map that streamlines the workflow and maximizes value.

How to Implement Value Stream Mapping

VSM involves creating a visual flowchart of every action involved in a specific process. This video offers a clear introduction to the fundamentals of creating and using a value stream map.

The visual guide explains how to map both material and information flows, a crucial aspect of this business process improvement technique that sets it apart from simple process mapping.

Practical Tips for Application

To effectively leverage Value Stream Mapping, consider these actionable steps:

- Walk the Process: Physically follow the material and information flow from start to finish to gain firsthand insights and verify data. This is known as a "gemba walk."

- Involve Cross-Functional Teams: Include stakeholders from every stage of the process in mapping sessions to ensure a comprehensive and accurate representation.

- Focus on One Product Family: Begin with a single product or service family to keep the scope manageable and achieve a clear, impactful improvement.

- Design the Future State First: Before making any changes, create a detailed map of the ideal future state. This provides a clear target and helps align the improvement efforts.

This methodology is ideal for organizations seeking to reduce lead times and improve overall process efficiency. For instance, Intel famously used VSM to cut its product development cycle time by 40%, demonstrating its significant impact.

7. Agile Methodology

Agile is an iterative approach to project management and business process improvement that prioritizes flexibility, collaboration, and rapid delivery of value. Originally from the software world, Agile principles now help various business functions adapt to change. It breaks down large projects into small, manageable increments called sprints, allowing teams to deliver value quickly and incorporate feedback continuously.

This methodology centers on adaptive planning, early delivery, and constant improvement. Instead of following a rigid plan, Agile teams respond to changes in real-time, making it an effective technique for dynamic environments where requirements evolve.

How to Implement Agile Methodology

Implementing Agile involves a cultural shift towards transparency, inspection, and adaptation. Teams typically work in short cycles (sprints), hold daily stand-up meetings to align on progress, and regularly review their work and processes in sprint reviews and retrospectives. This creates a continuous feedback loop that drives improvement.

The focus is on delivering functional pieces of a project quickly, gathering real-world feedback, and iterating based on those insights. This minimizes risk and ensures the final output closely aligns with customer needs.

Practical Tips for Application

To effectively leverage Agile as one of your core business process improvement techniques, consider these actionable steps:

- Start with Pilot Projects: Introduce Agile with a small, motivated team on a single project to build experience and demonstrate value before scaling.

- Invest in Training and Coaching: Equip teams with a solid understanding of Agile principles and practices, like Scrum or Kanban, through professional coaching.

- Establish Clear Roles: Define roles such as Product Owner and Scrum Master to ensure accountability and smooth workflow management.

- Use Visual Management Tools: Employ tools like Kanban boards to provide transparency on work progress, bottlenecks, and priorities.

This adaptive framework is ideal for organizations in fast-paced industries needing to innovate and respond to market changes swiftly, as seen in transformations at companies like ING Bank and John Deere.

8. Theory of Constraints (TOC)

Theory of Constraints (TOC) is a management philosophy that views any complex system as a chain of linked processes, with the overall performance limited by its weakest link, or "constraint." Developed by Dr. Eliyahu Goldratt, TOC is a powerful business process improvement technique focused on identifying and systematically improving this single limiting factor to elevate the entire system's output. Instead of spreading improvements thinly across all areas, TOC concentrates all efforts on the one part of the process that is holding everything else back.

This approach follows a cyclical, five-step focusing process. By identifying the constraint and reorganizing all other operations around maximizing its efficiency, businesses can achieve rapid and significant improvements in throughput and overall performance.

How to Implement the Five Focusing Steps

The Five Focusing Steps provide a clear framework for applying TOC. It is an iterative process designed to continuously identify and eliminate bottlenecks as they shift within the system.

- Identify the system’s constraint.

- Exploit the constraint by ensuring it operates at maximum capacity.

- Subordinate all other processes to support the constraint's needs.

- Elevate the constraint’s capacity if it remains a bottleneck.

- Repeat the process by looking for the next constraint.

This continuous cycle ensures that improvement efforts are always directed at the most critical point in the system, preventing wasted resources and driving sustainable growth.

Practical Tips for Application

To effectively apply the Theory of Constraints, consider these actionable steps:

- Identify the True Constraint: Look beyond symptoms to find the actual root bottleneck. This could be a machine, a policy, or a person.

- Maximize Constraint Uptime: Ensure the constraint is never idle. Schedule breaks and maintenance around its operation and give it priority for resources.

- Align Supporting Processes: Adjust the pace and priorities of all non-constraint processes to serve the needs of the constraint, preventing it from being starved of work or overwhelmed.

- Avoid Premature Investment: Only consider adding capacity (e.g., buying new equipment) after you have fully exploited and subordinated the existing constraint.

TOC is ideal for organizations looking to dramatically improve flow and output without significant capital investment. For example, Delta Airlines used TOC to increase its aircraft utilization by 15%, demonstrating its effectiveness in complex operational environments.

9. Process Mining

Process Mining is an analytical discipline that uses event log data from IT systems to discover, monitor, and improve real business processes. Spearheaded by pioneers like Wil van der Aalst, it provides an objective, data-driven view of how work is actually done, bridging the gap between prescribed process maps and on-the-ground reality. By analyzing digital footprints, it automatically visualizes process flows, revealing bottlenecks, deviations, and inefficiencies.

This technique acts like an X-ray for your operations, showing you the true path of every transaction or case. By moving beyond assumptions and interviews, process mining offers concrete evidence of where and why delays occur, empowering organizations to make targeted, high-impact changes.

How Process Mining Uncovers Hidden Inefficiencies

Process mining software connects to systems like your ERP or CRM to extract event logs. These logs, which contain a case ID, activity name, and timestamp, are then used to reconstruct a visual map of the entire process. This map highlights the most common process paths as well as costly exceptions and rework loops that might otherwise go unnoticed.

The visual representation makes complex operational data easy to understand, allowing teams to pinpoint the root causes of performance issues with precision. To learn more about this analytical approach to process improvement, read our article on What Is Process Mining?

Practical Tips for Application

To effectively implement this business process improvement technique, consider these steps:

- Start with Rich Data: Begin with a process that generates detailed event logs, such as order-to-cash or procure-to-pay, to ensure you have sufficient data for analysis.

- Ensure Data Quality: Clean and validate the event log data to guarantee accuracy. Incomplete or inconsistent data can lead to flawed conclusions.

- Combine with Expertise: Pair data insights with the knowledge of process owners and subject matter experts who can provide crucial context for why deviations occur.

- Focus on High Impact: Target frequently executed, high-volume processes where even small improvements can yield significant financial or operational benefits.

This technique is ideal for complex, data-rich environments where process adherence is critical. Companies like Siemens have used it to improve invoice processing by 20%, demonstrating its power to drive measurable results.

Top 9 Business Process Improvement Techniques Comparison

| Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Six Sigma | High - structured DMAIC/DMADV | High - training, data analysis | Near-perfect quality (3.4 defects per million) | Large organizations with complex process quality issues | Data-driven, measurable ROI, continuous improvement |

| Lean Manufacturing/Lean Thinking | Medium-High - cultural change | Medium - workforce training | Waste reduction, faster delivery, cost savings | Manufacturing, healthcare, services with repetitive processes | Waste elimination, employee empowerment |

| Business Process Reengineering (BPR) | Very High - radical redesign | Very High - investment, technology | Dramatic productivity and quality improvements | Organizations needing breakthrough transformation | Breakthrough improvements, competitive advantage |

| Kaizen (Continuous Improvement) | Low - incremental changes | Low - employee involvement | Sustainable long-term improvements | Organizations seeking culture change and engagement | Low risk, quick wins, continuous improvement |

| Total Quality Management (TQM) | High - organization-wide effort | High - cultural and training investment | Long-term quality and customer satisfaction | Organizations committed to quality excellence | Strong quality culture, customer focus |

| Value Stream Mapping (VSM) | Low-Medium - process visualization | Low - cross-functional workshops | Identifies waste and bottlenecks | Manufacturing and service processes with clear flow | Clear visualization, collaboration facilitation |

| Agile Methodology | Medium - iterative adoption | Medium - training and coaching | Faster delivery, flexibility, customer satisfaction | Complex, uncertain environments needing adaptability | Flexibility, collaboration, rapid value delivery |

| Theory of Constraints (TOC) | Medium - focused constraint work | Medium - systems thinking needed | Quick, focused improvements on bottlenecks | Organizations with clear bottlenecks and capacity limits | Focused improvements, simple methodology |

| Process Mining | Medium - data-driven implementation | Medium-High - software, skills | Real-time, objective process insights | Organizations with digital processes and event logs | Automated insights, real-time monitoring |

Putting Theory into Practice: Your Next Step

Navigating the landscape of business process improvement techniques can feel like learning a new language. From the data-driven precision of Six Sigma to the incremental, human-centric philosophy of Kaizen, each methodology offers a unique lens through which to view and refine your organization's operations. We've explored a powerful toolkit, including the radical change of Business Process Reengineering (BPR), the customer-focused principles of Total Quality Management (TQM), and the bottleneck-busting logic of the Theory of Constraints (TOC).

The true value, however, isn't in just understanding these frameworks; it's in their strategic application. The most successful organizations don't randomly adopt a new technique. Instead, they diagnose their specific challenges and select the tool that best fits the job. Your journey toward operational excellence begins not with a massive, company-wide mandate, but with a single, well-defined problem.

From Knowledge to Action: Your Implementation Roadmap

The transition from theory to practice is where real transformation occurs. There is no universal "best" method; the ideal approach is situational. A startup struggling with rapid product iterations might find immense value in Agile, while a mature manufacturing firm could uncover hidden inefficiencies with Value Stream Mapping (VSM).

Your next steps shouldn't be daunting. Follow this simple, actionable plan to get started:

- Identify a High-Impact Process: Pinpoint one specific workflow that is a known source of frustration, cost, or delay. Is it customer onboarding? Inventory management? The software deployment pipeline? Start where the pain is most acute.

- Align the Technique to the Goal: Match your chosen methodology to the scale and nature of the problem. Are you aiming for a 1% daily improvement? That’s a perfect fit for Kaizen. Do you need to fundamentally rethink how a core service is delivered? BPR might be the answer. Is your process bogged down by digital data? Process Mining can reveal the hidden bottlenecks.

- Build a Cross-Functional Team: Process improvement is not a solo endeavor. Assemble a small, dedicated team of individuals who are directly involved in the process you're targeting. Their firsthand knowledge is your most valuable asset.

- Measure, Implement, and Iterate: Establish clear metrics for success before you begin. Implement the changes on a small scale, measure the results against your baseline, and use the data to refine your approach. This creates a feedback loop that builds momentum and demonstrates value.

Ultimately, mastering these business process improvement techniques is about cultivating a culture of relentless curiosity and continuous optimization. It's about empowering your teams to see waste, challenge assumptions, and build better, smarter ways of working. This journey transforms your operations from a collection of static tasks into a dynamic, adaptable system that drives sustainable growth and competitive advantage.

Ready to eliminate a major source of digital waste in your new workflows? Bloated files slow down transfers, increase cloud storage costs, and create bottlenecks. Compresto uses cutting-edge compression technology to dramatically reduce file sizes without sacrificing quality, perfectly aligning with Lean principles of waste reduction. Discover how you can make your digital processes faster and more efficient by visiting Compresto today.

Article created using Outrank