9 Process improvement techniques You Should Know

In any organization, the pursuit of efficiency is a constant. Teams are always looking for ways to do more with less, eliminate waste, and deliver higher quality results. The challenge isn't recognizing the need for improvement; it's knowing where to start. With countless frameworks and methodologies available, selecting the right approach can feel overwhelming. This guide cuts through the noise, providing a curated collection of the most effective process improvement techniques used by leading companies worldwide.

We will move beyond theory and focus on practical application. You will learn not just what each technique is, but how to implement it within your team or department. Before diving into specific methodologies like Six Sigma or Kaizen, understanding the foundational principles of workflow optimization is crucial. For those just getting started, learning how to streamline your operations provides a solid base for the advanced methods we'll explore.

This article is designed to be your actionable playbook. For each of the nine techniques covered, we will detail its core principles, identify ideal use-cases, and provide clear, step-by-step guidance for implementation. Whether you aim to reduce production defects, shorten project timelines, or simply foster a culture of continuous improvement, you will find the tools you need right here. Let's get started.

1. Six Sigma

Six Sigma is a highly disciplined, data-driven methodology that uses statistical analysis to eliminate defects and improve quality in any process. Originating at Motorola and famously championed by Jack Welch at General Electric, this technique aims for a level of quality that is 99.99966% defect-free, which translates to no more than 3.4 defects per million opportunities (DPMO). It’s one of the most rigorous process improvement techniques available for achieving quantifiable financial returns.

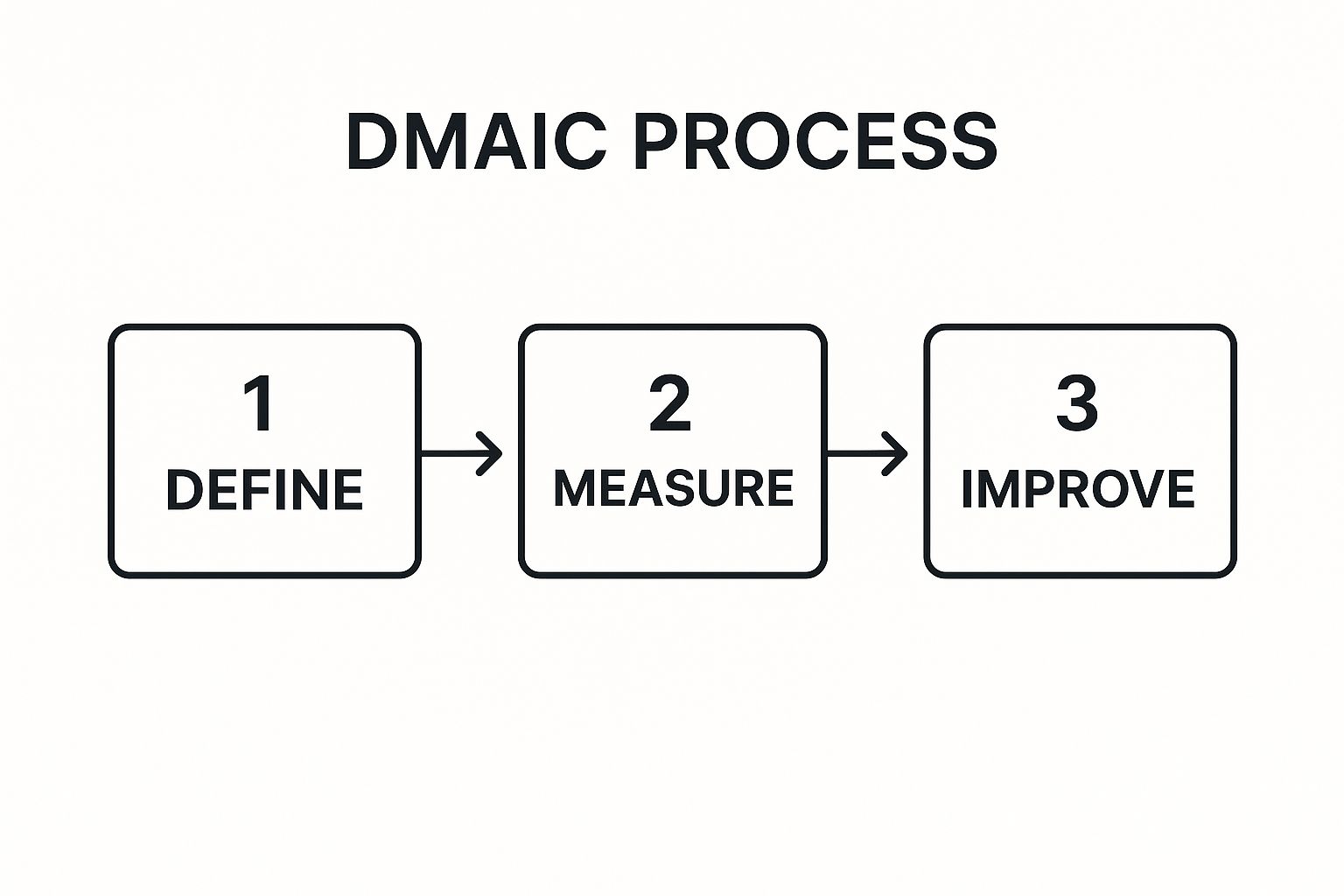

At its core, Six Sigma identifies and removes the causes of errors and minimizes variability in manufacturing and business processes. It relies on a structured framework known as DMAIC (Define, Measure, Analyze, Improve, Control) to systematically guide projects toward their goals.

When to Use Six Sigma

Six Sigma is most effective for solving complex problems with unknown causes. It's ideal for situations where you need to drastically reduce high defect rates, improve customer satisfaction, or achieve significant cost savings. Companies like General Electric, which reported saving $12 billion in five years, use it to tackle high-stakes operational challenges.

Actionable Tips for Implementation

- Start Small: Begin with high-impact, visible projects to build momentum and demonstrate value.

- Secure Leadership Buy-In: Ensure senior management actively supports and participates in the initiative.

- Invest in Training: Proper training and certification (e.g., Green Belt, Black Belt) are crucial for success.

- Focus on the Customer: Prioritize processes that are critical to customer satisfaction and quality.

The DMAIC framework provides a clear path for executing a Six Sigma project. The following infographic illustrates the foundational steps of this workflow.

This process flow highlights how each stage builds upon the last, moving from identifying the problem to implementing a validated solution.

2. Lean Manufacturing

Lean Manufacturing is a systematic approach to identifying and eliminating waste, known as muda, within production systems while maximizing customer value. Developed from the Toyota Production System, it emphasizes continuous improvement (kaizen) by empowering employees to refine processes and deliver products through a just-in-time methodology. This is one of the most foundational process improvement techniques for creating efficient, customer-centric operations.

At its heart, Lean focuses on creating more value for customers with fewer resources. It achieves this by meticulously analyzing workflows to remove non-value-added activities, thereby streamlining production, reducing costs, and improving quality.

When to Use Lean Manufacturing

Lean is exceptionally powerful when your primary goals are to increase efficiency, reduce inventory, and shorten cycle times. It is ideal for environments where you need to improve workflow and eliminate bottlenecks without a major capital investment. For instance, Toyota famously used Lean principles to reduce inventory levels by 75%, while Nike slashed its production lead time from six months down to just six weeks.

Actionable Tips for Implementation

- Start with 5S: Implement the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to create an organized and efficient workspace as a foundation for broader changes.

- Map Your Value Stream: Use value stream mapping (VSM) to visualize your entire process, from raw materials to the final customer, to clearly identify areas of waste.

- Implement a Pull System: Gradually shift from a "push" system (making products in anticipation of demand) to a "pull" system where production is triggered by actual customer orders.

- Focus on Small, Continuous Improvements: Encourage a culture of kaizen, where all employees are empowered to make small, incremental improvements consistently rather than waiting for large-scale overhauls.

3. Kaizen

Kaizen is a Japanese philosophy centered on continuous, incremental improvement involving every employee, from the C-suite to the front line. Popularized by figures like Masaaki Imai and Taiichi Ohno of Toyota, it promotes the idea that small, ongoing positive changes can reap significant long-term benefits. Rather than pursuing radical, disruptive overhauls, Kaizen focuses on making work more efficient, effective, and fulfilling on a daily basis. It stands as one of the most foundational process improvement techniques for fostering a culture of ownership and proactive problem-solving.

At its heart, Kaizen is less a project-based tool and more an organizational mindset. It encourages teams to constantly look for waste, eliminate unnecessary steps, and standardize best practices.

When to Use Kaizen

Kaizen is best applied when you want to build a sustainable culture of improvement rather than just fixing a single, isolated issue. It is ideal for organizations aiming to empower employees, boost morale, and achieve consistent gains in quality and efficiency over time. Companies like Toyota, which famously implements around one million employee-driven ideas annually, use it to maintain a competitive edge. Similarly, Lockheed Martin successfully used Kaizen principles to reduce aircraft production time by 40%, demonstrating its power in complex manufacturing.

Actionable Tips for Implementation

- Empower Everyone: Encourage all employees to submit improvement ideas, no matter how small. Implement suggestion systems with clear feedback loops.

- Go to the Source: Conduct regular "gemba walks" (going to the actual workplace) to observe processes firsthand and identify opportunities for improvement.

- Celebrate Small Wins: Publicly recognize contributors and celebrate successful small changes to build momentum and reinforce the culture.

- Standardize Success: Once an improvement is validated, standardize it across relevant teams to lock in the gains and create a new baseline.

4. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a radical improvement strategy that involves completely rethinking and redesigning core business processes to achieve dramatic improvements in critical measures of performance, such as cost, quality, service, and speed. Unlike incremental improvements, BPR challenges fundamental assumptions and seeks to create entirely new, more efficient workflows from the ground up. This technique was famously championed by thinkers like Michael Hammer and James Champy.

At its core, BPR is a "clean slate" approach. It starts by identifying the desired outcome of a process and then works backward to build a new system, often leveraging technology to enable new ways of working. This focus on radical redesign makes it one of the most transformative process improvement techniques for organizations willing to undergo significant change.

When to Use Business Process Reengineering (BPR)

BPR is most effective when a company's processes are fundamentally broken, outdated, or unable to meet competitive demands. It is ideal for situations requiring massive performance gains, not just small tweaks. For example, Ford famously used BPR to reduce its accounts payable staff by 75% by reengineering the entire invoicing and payment process, while IBM Credit cut its loan approval time from seven days to just four hours.

Actionable Tips for Implementation

- Secure Strong Executive Sponsorship: BPR involves major organizational shifts, making unwavering support from top leadership non-negotiable.

- Focus on High-Impact Processes: Begin with processes that directly impact customer value or have significant cost implications to demonstrate clear ROI.

- Invest Heavily in Change Management: Prepare the organization for disruption. Communicate openly, provide training, and manage employee resistance to new systems.

- Use Technology as an Enabler: View technology not just as a tool for automation but as a way to invent entirely new ways of performing work.

5. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive management philosophy where continuous improvement is woven into the very fabric of an organization. Pioneered by quality gurus like W. Edwards Deming, it asserts that quality is not just a final inspection but a collective responsibility that involves every employee in every department. TQM focuses on long-term success through customer satisfaction, aiming to integrate all organizational functions to improve processes, products, and services.

At its heart, TQM is a cultural shift. It moves an organization from detecting defects to proactively preventing them. This approach is one of the most holistic process improvement techniques because it empowers the entire workforce to contribute to quality, fostering a commitment to excellence from the top down.

When to Use TQM

TQM is ideal for organizations seeking to build a sustainable culture of quality and customer focus rather than just solving a single, isolated problem. It’s best applied when you need to improve processes across the entire company, enhance customer loyalty, and boost employee morale. For example, Xerox successfully used TQM principles to regain market share from competitors by overhauling its quality standards company-wide.

Actionable Tips for Implementation

- Secure Leadership Commitment: TQM must be driven from the top. Leaders need to champion, fund, and model the quality-first mindset.

- Focus on the Customer: Center all improvement efforts around meeting and exceeding customer requirements. Use feedback loops like surveys and focus groups.

- Empower All Employees: Provide training and delegate authority so employees can identify and address quality issues in their own work.

- Establish Quality Measurement: Implement systems to track performance metrics across all processes, making data-driven decisions the norm.

- Create Cross-Functional Teams: Assemble teams from different departments to solve process-related problems, breaking down organizational silos.

6. Value Stream Mapping

Value Stream Mapping (VSM) is a visual, lean-management tool used to analyze and improve the flow of materials and information required to bring a product or service from its beginning to the customer. Popularized by practitioners of the Toyota Production System like Mike Rother and John Shook, VSM creates a detailed diagram of every step in a process. This makes it one of the most effective process improvement techniques for visualizing waste and bottlenecks.

At its core, VSM involves creating two maps: a "current state" map that shows the process as it is, and a "future state" map that illustrates the ideal, streamlined process. By comparing these two, teams can identify non-value-added activities and create a clear, actionable plan for improvement.

When to Use Value Stream Mapping

VSM is ideal when you need a holistic view of an entire process flow, rather than just focusing on individual steps. It's particularly useful for identifying systemic issues like excessive wait times, inventory buildup, or information delays. For instance, Toyota famously used VSM principles to slash car manufacturing lead times, while Seattle Children's Hospital reduced patient wait times by 50% by redesigning their process flows.

Actionable Tips for Implementation

- Walk the Gemba: Physically walk through the process yourself to observe it firsthand. Do not rely on secondhand information.

- Involve the Team: Include employees who actually perform the work in the mapping process to ensure accuracy and gain buy-in.

- Focus on One Product Family: Avoid complexity by mapping the value stream for a single product or service family at a time.

- Use Data: Collect real-time data on cycle times, wait times, and inventory levels to accurately identify bottlenecks.

This video provides a practical overview of how to create and use a value stream map to drive meaningful change.

By following the VSM workflow, organizations can move from understanding a problem to implementing a targeted solution that eliminates waste and delivers more value to the customer.

7. Plan-Do-Check-Act (PDCA) Cycle

The Plan-Do-Check-Act (PDCA) cycle, also known as the Deming Cycle, is an iterative, four-stage management method used for the continuous improvement of processes and products. It provides a simple yet powerful scientific approach to making changes and solving problems. This framework guides organizations to test potential solutions on a small scale, assess their effectiveness, and then implement them more broadly if successful.

At its core, PDCA is a cyclical learning and improvement model. It starts with planning a change (Plan), moves to testing it (Do), then measures the results (Check), and finally takes action based on what was learned (Act). This systematic loop ensures that improvements are based on data, not assumptions, making it one of the most fundamental process improvement techniques for building a culture of continuous learning.

When to Use the PDCA Cycle

The PDCA cycle is ideal for implementing gradual, incremental improvements rather than radical overhauls. It works exceptionally well when starting a new improvement project, developing a new or improved product design, or implementing any change that requires testing and validation. For instance, Virginia Mason Medical Center successfully used PDCA to enhance patient safety protocols, and Starbucks continuously uses it to optimize in-store operations and customer flow.

Actionable Tips for Implementation

- Start Small: Begin with manageable, low-risk changes to test hypotheses without disrupting major operations.

- Document Each Step: Keep detailed records of your plans, actions, data, and results to create a clear audit trail for learning.

- Use Data to Validate: Base your decisions in the "Check" phase on quantitative or qualitative data, not just gut feelings.

- Involve Team Members: Engage employees at all levels in each phase to gather diverse perspectives and foster collective ownership.

- Complete the Cycle: Avoid the common pitfall of stopping after the "Do" phase. The "Check" and "Act" stages are critical for learning and standardization.

8. Root Cause Analysis

Root Cause Analysis (RCA) is a systematic problem-solving method designed to identify the fundamental, underlying causes of an incident or problem, rather than simply addressing the immediate symptoms. By digging deeper into an issue, RCA helps organizations implement solutions that prevent the problem from happening again. It’s one of the most foundational process improvement techniques for creating lasting change and enhancing safety and quality.

Pioneered by figures like Sakichi Toyoda with his "5 Whys" and Kaoru Ishikawa with the "Fishbone Diagram," RCA is not a single technique but a collection of tools used to uncover the true origin of a defect or failure. It moves the focus from blaming individuals to understanding and correcting flaws within systems and processes.

When to Use Root Cause Analysis

RCA is essential for investigating significant or recurring problems, such as safety incidents, major quality failures, or persistent operational bottlenecks. It is widely used in high-stakes industries where preventing recurrence is critical. For example, NASA has famously used RCA to analyze accidents like the Space Shuttle Challenger and Columbia disasters to prevent future tragedies, while healthcare systems use it to drastically reduce medical errors.

Actionable Tips for Implementation

- Gather Diverse Perspectives: Involve team members from different departments and levels who interact with the process. This provides a holistic view of the problem.

- Focus on Systems, Not Blame: Create a psychologically safe environment where the goal is to fix the process, not to assign fault to individuals.

- Use Multiple Analysis Tools: Combine methods like the 5 Whys, Fishbone Diagrams, and Fault Tree Analysis to get a comprehensive understanding of complex issues.

- Validate with Data: Don't rely on assumptions. Use data and evidence to confirm that you have identified the true root cause before implementing solutions.

9. 5S Methodology

The 5S Methodology is a workplace organization system that uses five Japanese principles to create and maintain an efficient, clean, and safe work environment. The five steps are Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). By establishing a foundation of discipline and order, 5S is one of the most fundamental process improvement techniques for eliminating waste.

At its heart, 5S clears clutter and organizes tools, materials, and information so they are easily accessible and in their proper place. This systematic approach reduces wasted time searching for items, minimizes errors, improves safety, and boosts employee morale. It serves as a launchpad for more complex lean initiatives like Kaizen or Kanban.

When to Use 5S Methodology

5S is best implemented when a workspace is disorganized, inefficient, or unsafe. It is a powerful first step for any organization starting its continuous improvement journey. Companies like Boeing, which reduced tool search time from eight hours to just 45 minutes per shift, use it to address foundational inefficiencies. It's ideal for environments where visual management and immediate access to tools are critical for productivity.

Actionable Tips for Implementation

- Start with a Pilot Area: Select a specific department or work cell to demonstrate the benefits and refine your approach before a full-scale rollout.

- Involve Employees Directly: Empower the team members who use the workspace to design the new organization systems. Their buy-in is essential for sustainability.

- Use Visual Controls: Implement extensive labeling, color-coding, and shadow boards to make it obvious where everything belongs and when something is missing.

- Conduct Regular Audits: Perform scheduled 5S audits to measure compliance, identify areas for improvement, and reinforce the standards.

Process Improvement Techniques Comparison

| Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Six Sigma | High 🔄🔄🔄 | Significant (training, certification) ⚡⚡ | Near-zero defects, measurable cost savings 📊📊 | Complex, data-driven process improvement 💡 | Data-driven, structured DMAIC, strong ROI, quality focus ⭐ |

| Lean Manufacturing | Medium 🔄🔄 | Moderate (training, cultural change) ⚡ | Waste reduction, faster production, better quality 📊 | Manufacturing efficiency, waste elimination 💡 | Reduces inventory/waste, speed improvement, employee engagement ⭐ |

| Kaizen | Low to Medium 🔄🔄 | Low to Moderate (culture & discipline) ⚡ | Continuous small improvements, sustained culture 📊 | Incremental process improvements, employee involvement 💡 | Low cost, builds engagement, sustainable improvement culture ⭐ |

| Business Process Reengineering (BPR) | Very High 🔄🔄🔄🔄 | High (resources, investment) ⚡⚡⚡ | Radical productivity and quality improvements 📊📊📊 | Major process overhaul, breakthrough gains 💡 | Breakthrough improvements, new structures, tech leverage ⭐ |

| Total Quality Management (TQM) | High 🔄🔄🔄 | Significant (long-term commitment) ⚡⚡ | Improved customer satisfaction & loyalty 📊 | Organization-wide quality culture 💡 | Comprehensive, total involvement, competitive advantage ⭐ |

| Value Stream Mapping | Medium 🔄🔄 | Moderate (time, training) ⚡ | Process visualization, waste identification 📊 | Process analysis and improvement planning 💡 | Clear visualization, cross-functional collaboration ⭐ |

| Plan-Do-Check-Act (PDCA) | Low 🔄 | Low (discipline and documentation) ⚡ | Iterative learning, reduced risk, continuous improvement 📊 | Ongoing process/product improvement 💡 | Simple, risk-reducing, promotes learning and culture ⭐ |

| Root Cause Analysis | Medium to High 🔄🔄🔄 | Moderate (skilled facilitators) ⚡⚡ | Problem prevention, addressing fundamental causes 📊 | Troubleshooting and problem-solving 💡 | Prevents recurrence, develops analytic skills ⭐ |

| 5S Methodology | Low 🔄 | Low (employee involvement, discipline) ⚡ | Organized workplace, improved safety and efficiency 📊 | Workplace organization and foundation for improvements 💡 | Simple, boosts discipline, reduces search time ⭐ |

Final Thoughts

We've explored a powerful arsenal of process improvement techniques, from the data-driven precision of Six Sigma to the incremental, human-centric philosophy of Kaizen. While each method offers a unique lens for viewing and refining your operations, they all share a common, foundational goal: to replace guesswork with a structured approach to creating value, eliminating waste, and boosting efficiency. The journey from inefficiency to optimization is not about finding a single magic bullet. Instead, it's about building a versatile toolkit and understanding which tool is right for the specific challenge at hand.

Whether you're tackling a complex, cross-departmental workflow with Business Process Reengineering or organizing a single workstation with the 5S Methodology, the core principle remains the same. You must first see the process, then understand it, and only then can you effectively improve it. Techniques like Value Stream Mapping provide the vision, while methods like Root Cause Analysis ensure your solutions address the disease, not just the symptoms.

Your Next Steps to Process Mastery

The true value of these process improvement techniques is unlocked not through passive reading but through active application. To move from theory to tangible results, consider these immediate next steps:

- Start Small: Don't attempt to overhaul your entire organization at once. Select a single, manageable, and noticeable pain point. Perhaps it’s a consistently delayed reporting process or a cluttered digital filing system. Apply a simple framework like the PDCA cycle to implement and test a change.

- Identify the Right Tool: Review the challenges you face. Are they related to quality and defects (Six Sigma)? Waste and flow (Lean)? A disorganized workspace (5S)? Matching the problem to the appropriate technique is the most critical first step.

- Empower Your Team: Lasting improvement is a team sport. Introduce these concepts to your colleagues and foster a culture where suggesting changes is encouraged and celebrated. A core tenet of Total Quality Management and Kaizen is that the people doing the work are often the most qualified to improve it.

- Document Everything: As you implement changes, track your progress. Document the initial state, the changes made, and the results. This data not only proves the value of your efforts but also creates a valuable knowledge base for future optimization projects.

Ultimately, mastering these process improvement techniques transforms your approach from reactive problem-solving to proactive, strategic optimization. It equips you and your team with a shared language and a structured methodology to build more resilient, efficient, and successful operations. The path to continuous improvement is a marathon, not a sprint, but every step forward creates lasting value.

As you refine your digital workflows, managing file sizes becomes a critical part of process efficiency. Compresto helps you master your digital assets by intelligently compressing images, videos, and documents without sacrificing quality. Integrate file optimization into your improved processes and keep your projects running smoothly with Compresto.